SRC Rack conveyor dishwasher New range

A new generation of washing tunnels arrives. Available from the first week of March.

Your washing area, in full production

Sammic has different combinations of modules to provide the production that best fits the needs of your business.

Optimisation in the integration of the components involved in the tasks of washing and rinsing has led to an improvement of 30% in the production capacity compared to the previous generation of dishwashers, achieving a production of up to 5,000 plates/hour.

All models offer 2 speeds to adapt to the circumstances of the demand and the level of soiling of the items.

The stopping and timing of the rack conveyor system are managed by the micro at the end of the line, which prevents blockages inside the tunnel and the unnecessary operation of the machine.

The use of space of this model can be increased by the corner loading table or our new corner drying module.

Results that speak for themselves

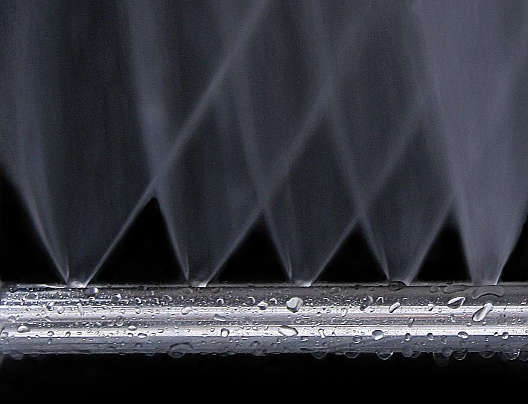

The cleaning pipes, with stainless steel nozzles, are strategically arranged for high-efficiency washing.

The nozzles of the washing arms have been designed to make maximum use of the pressure generated by the wash pumps.

The high-efficiency rinsing diffusers provide extensive sprinkling for perfect results in minimum space.

The separation of the different work areas with intermediate curtains prevents the washing water interfering in the rinsing stage.

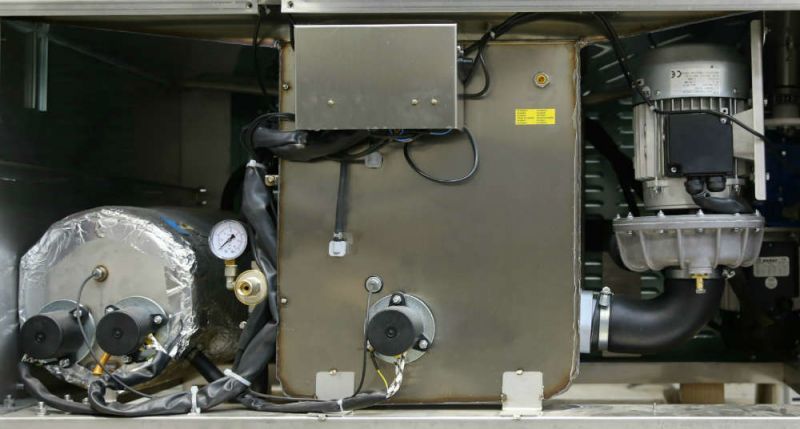

The high power of the boiler makes continuous operation possible without temperature drops. Thus, high temperature rinsing is guaranteed, to ensure the items are sanitised.

The user can constantly monitor the temperatures using the digital display on the control panel.

Smart Resource Management

One of the highest costs of operating dishwashers is the consumption of water used for rinsing the items. This is why we have designed a rinsing system for our dishwashers to provide a balance between efficacy and responsible water consumption. This commitment is achieved thanks to the optimised design of the diffusers and the introduction of a pressure reducer that regulates the amount of water that enters the boiler.

Sammic dishwashers are equipped with basket detectors throughout the route, automatically pausing operation if there is no basket inside.

The temperature is controlled with precision probes, which enable more efficient management of electricity consumption.

Your machine, always ready

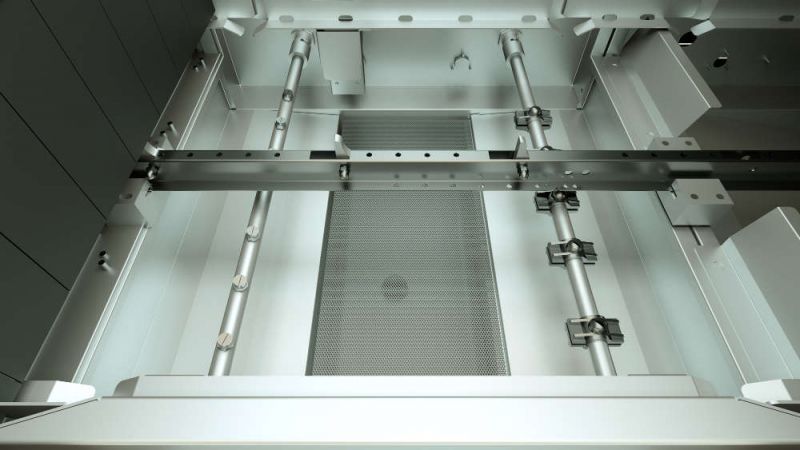

Each module is equipped with a wide door with assisted opening providing safe, easy access for cleaning and inspection tasks.

The cleaning and rinsing arms can be easily removed for cleaning. Correct maintenance of these components will enable you to enjoy an optimum level of performance.

The drums of washing water have sloping stainless steel filters and removable baskets for collecting waste. This prevents dirt falling into the drum, ensuring the washing water stays in optimal conditions for longer. The end benefit is to be able to change the water in the drum less frequently, saving resources and avoiding production stoppages.

The boiler may be emptied simply by releasing a hose, a significant factor when carrying out maintenance work on the machine.

Sammic dishwashers incorporate a breakdown self-diagnostics function: incidents are reported to the user by warning lights and/or an error code.

The machines have been designed so they can be repaired without having to remove them from their position, minimising downtime and maintenance costs.

Inlet and outlet splash guards are included as standard to avoid water splashes in the work environment.

The wash pumps are in a vertical position for self-draining, avoid bad odours and the possible deterioration of components in continuous contact with water.

Advanced performance, simplicity of use

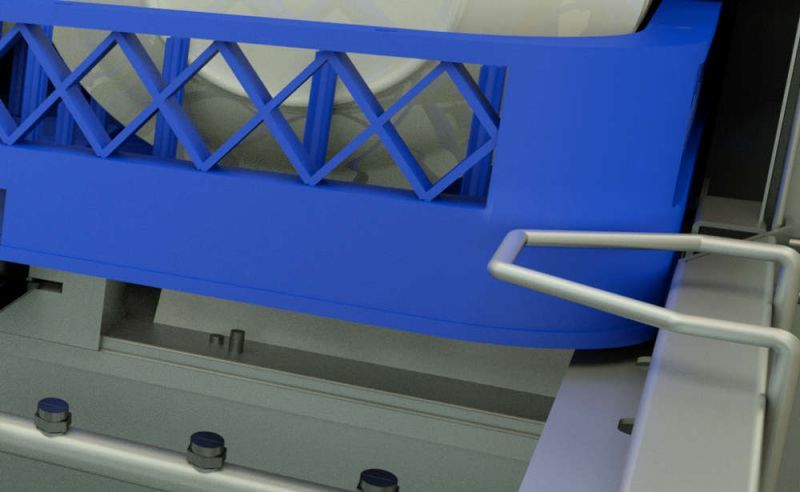

The basket conveyor system is based on a robust stainless steel frame.

All the dishwashers are equipped with the BPS (Blocking Guard System) system exclusive to Sammic. This technical innovation is based on the incorporation of movement detectors in strategic areas of the conveyor mechanism. When the BPS system detects that the progress speed of the mechanism drops below a safety level, it interprets this as a blockage and automatically disconnects the conveyor motor, thus avoiding damage to the machine itself or to the items to be washed.

When a basket is inserted, the machine starts automatically, improving the working dynamic and avoiding wasting time with unnecessary operation of the control panel.

The automatic filling of the boiler minimises the risk of failure in the resistors.

The SRC range is equipped with a new control panel, with a design that facilitates a more intuitive operation of the machine.

Your machine, something you can rely on

All models are fully made of stainless steel to provide a high resistance to corrosion and a greater durability.

Thanks to the oversizing of the main components and systems, advanced durability is guaranteed in all models.

The product design is based on achieved know-how over decades of Sammic experience in the field of dishwashing, as well as close collaboration with users of these types of products.

In addition, your machine shall be always be ready, thanks to our team of technical professionals who will provide excellent after-sales service.

a solution for every need

Prewash

This module is installed prior to the conventional washing stage. Its principal aim is to remove grease and waste from the surface of the items with its powerful 1.2 HP pump and 4 washing arms. The dirt removed ends up in the surface filters over the module drum.

The prewash action allows the even the most encrusted dirt to be removed from the items, facilitating the final washing in the conventional washing stage.

In addition, the prewash stage prevents that the water in the drum of the wash module becoming prematurely saturated with dirt, reducing the frequency needed for changing the washing water.

Power Wash

The standard cleaning module has been given extra power in the wash pump and additional arms have been included for advanced efficacy.

This module comes in high production models designed for a context of intensive use and high demand.

Double Rinse

As production increases in a dishwasher, the task of rinsing becomes more complex. Aware of the importance proper rinsing for impeccable results, we offer the double rinse module.

It is an additional stage that removes a significant amount of the soap from the surface of the items, facilitating optimum rinsing in the final rinsing stage.

This double rinse module recirculates the water from the conventional rinsing stage with the objective of minimising consumption of both water and energy.

For a drying process that adapts to production and space

Linear Drying

The productivity of dishwashers can be increased by installing the linear drying module. The drying modules make it possible to attend to the peaks in demands more effectively and reduce labour costs by removing the manual task of drying, providing in addition a better finish to the items.

- Thermostatic temperature control

- Nozzles and lateral baffles designed to make optimum use of the hot air generated

- Incorporated drain for excess water

Two models available:

|

Features |

TS-600 |

TS-800 |

|

Fan capacity |

1 HP / 0.75 kW |

1.5 HP 7 1.1 kW |

|

Heating resistor |

6 kW |

9 kW |

|

Circulating air m3/h |

1,300 |

2,000 |

|

Length (mm. |

||

|

SRC-1800 |

+600 mm |

|

|

SRC-2200-5000 |

+400 mm |

+600 mm |

Corner Drying

All the advantages of the linear drying module with an curved output at 90º for installations that require it due to space issues.

|

Features |

TS-90 |

|

Fan capacity |

1.5 HP / 1.1 kW |

|

Heating resistor |

9 kW |

|

Circulating air m3/h |

2,000 |

|

Length (mm. |

|

|

SRC-1800 |

+900 mm |

|

SRC-2200-5000 |

+700 mm |

Steam extraction is not a problem

CV Steam Condenser

The installation of this module provides a number of significant improvements to the performance of the dishwasher.

Firstly, the steam condenser captures and condenses the steam to heat the water at the dishwasher inlet that supplies the boiler, obtaining an improvement in energy efficiency of the machine of 29%.

In addition, this pre-heating of input wa

In addition, this pre-heating of input water favours the recovery of the water temperature in the boiler, further improving the washing efficiency of the machine.

It prevents steam without the need to extract it to the exterior, improving the working conditions in terms of temperature and moisture.

- Fan in vertical position and motor with double seal to prevent moisture getting into the motor.

- Extractable filter to prevent grease getting in.

- Power: 750 W

EV Steam Extractor

The steam extractor is an alternative option to the installation of a steam condenser when managing the steam generated while the dishwasher is working.

The installation of a steam extractor module improves the working conditions in terms of temperature and moisture.

- Output diameter: 176 mm

- Removable grease filter

- Power: 550 W

CA Extraction Hood

The extraction hood is an accessory designed to remove the steam generated in the dishwasher using a remote extraction unit. It consists of a splash guard equipped with an outlet to connect to the extraction unit of the installation.

- Output diameter: 176 mm

- For models from SRC-2200

Rack conveyor dishwashers

Rack conveyor dishwashing machines with an hourly output of up to 5.500 dishes.

The rack conveyor dishwasher is ideal for schools, hotels, hospitals and large dining rooms.

- Production plates/hour (max)

| 1800 | Rack conveyor dishwasher SRC-1800 67/100 baskets per hour (1.800 plates/hour). |

| 2200 | Rack conveyor dishwasher SRC-2200 85/126 baskets per hour (2.200 plates/hour) |

| 2700 | Rack conveyor dishwasher SRC-2700 100/150 baskets per hour (2.700 plates/hour) |

| 3294 | Rack conveyor dishwasher SRC-3300 122/183 baskets per hour (3.300 plates/hour) |

| 3600 | Rack conveyor dishwasher SRC-3600 130/200 baskets per hour (3.600 plates/hour) |

| 4050 | Rack conveyor dishwasher SRC-4000 150/225 baskets per hour (4.050 plates/hour) |

| 4950 | Rack conveyor dishwasher SRC-5000 183/275 baskets per hour (4.950 plates/hour) |

Any questions?

Enter your enquiry